Toast is a breakfast staple in many households, and toasters are the go-to appliance for making it. But have you ever wondered how exactly your toaster works? While it may seem like a simple kitchen gadget, the science behind its functioning is more complex than you might think.

Toasters use radiant heat, or infrared radiation to be more specific, to toast bread. Once the bread’s surface reaches a temperature of around 310°F (155°C), a chemical process called the Maillard reaction starts. This causes the sugars and starches in the bread to turn brown and develop a distinct flavor.

In this article, we’ll delve deeper into the science behind toasters and uncover the mechanisms that turn bread into crispy, golden toast.

How Do Toasters Work?

As indicated above, the principle of making toast is pretty simple – all you need is radiant heat and bread. But what is radiant heat? Professor Louis A. Bloomfield from the Department of Physics at the University of Virginia helps us to understand:

“With radiant heat, the atoms and molecules exchange energy by sending thermal radiation back and forth. Thermal radiation is electromagnetic waves and includes infrared light. A hotter object sends more infrared light toward a colder object than vice versa, so the hotter object gives up thermal energy to the colder object.”

Fire sufficed for ages as the agent for applying radiant heat to bread. Still, with the coming of the electrical age, things became more complicated – not necessarily for the person toasting, but rather for the toasting device itself. Read on to learn about the inner workings of a variety of toasters.

Inside The Toaster

Different metals react differently to the flow of electric current. If a metal offers high resistance to the flow of electric current, it is not a good conductor. Because of the resistance of the wire, the electric current flowing through the wire causes heat. The best metals of high resistance are alloys – combinations of several metals – like nickel-chromium, better known by its trade name Nichrome.

A toaster’s heating element usually consists of a Nichrome ribbon wound on mica strips, although some toasters use Nichrome wire coils.

Depending upon their construction, most electric toasters will toast two slices of bread on both sides or two slices on one side at the same time. Electric toasters may conveniently be divided into three classes:

- Manual

- Semi-automatic

- Automatic

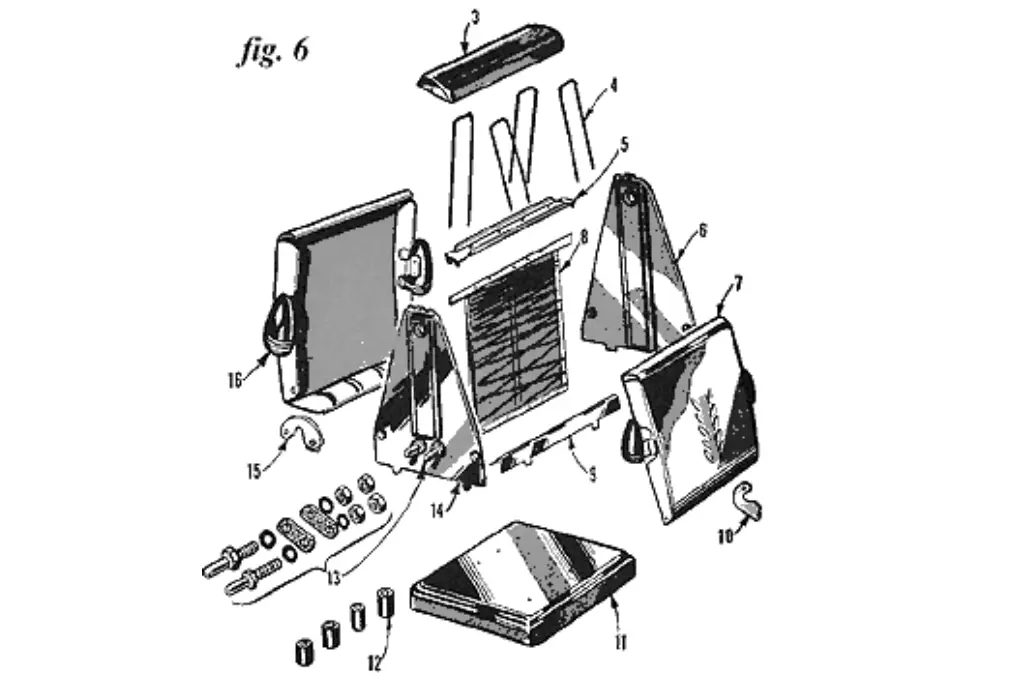

Manual Toasters: The earliest electric manual toasters had no moving parts and the bread was simply perched on the framework. But most manual toasters are usually of the open-element vertical type (fig. 6). Here the bread is placed on hinged racks, one on each side of the open heating element and after the bread is toasted on one side, then by turning the rack outward the bread simply slides down and reverses itself.

Although the vertical types are universally used, certain types of manual toasters of the open-element type are horizontal, in which case the bread is laid on a flat rack sometimes hinged and reversible.

It should be noted that in all manual toasters, the toasting period is left to the judgment of the operator. In most cases, it is necessary to turn the handle to reverse the toast.

Semi-Automatic Toasters: These differ from the manual type in that they incorporate certain signal features or annunciators, which normally consist of a bell that will signal the completion of the toasting period.

Other toasters of this classification include a thermostatic switch, in which the toasting period is thermostatically controlled by the surface temperature of the bread, but usually do not include the pop-up feature. Most toasters of the semi-automatic type also include a regulator in the form of a dial, which may be adjusted to the degree of brownness desired.

Automatic Toasters: There are a great variety of automatic toasters with somewhat different construction principles. In all cases, however, the electrical current in the heater element toasts the bread. The main difference in the various types lies in the method employed to control the toasting cycle. A great number of automatic toasters are classified as the “pop-up” type and include, in addition to the heating element, a thermostatic switch or timing device which automatically controls the toasting process.

When the operating lever is pressed down, the switch contacts are closed and they remain closed until the bread carriages are released. Thus, the units are energized from the time the operating lever handle is depressed until the bread pops up.

One type of automatic toaster contains a spring-actuated clock mechanism, in which the lowering of the operating handle with its bread carriage energizes the spring which action also completes the electrical circuit through the heating elements. At the completion of the toasting cycle, the clock automatically trips the carriage, which returns to its original position, opening the circuit through the heating element.

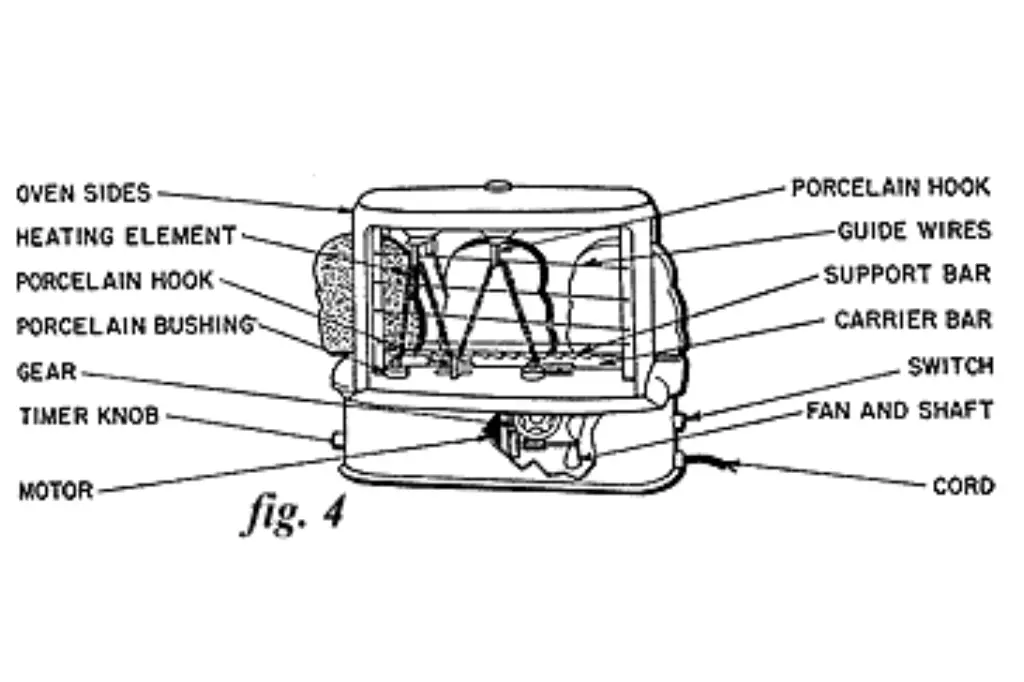

Other automatic toasters are of the so-called through type (fig. 4, below), in which the bread to be toasted is loaded in one end and expelled through the other, the movement of the bread being furnished by a carrier bar which in turn is being driven by a small electric motor.

Operation of Automatic Toasters

In order to obtain comprehensive knowledge about automatic toasters, it will be necessary to understand the method of operation.

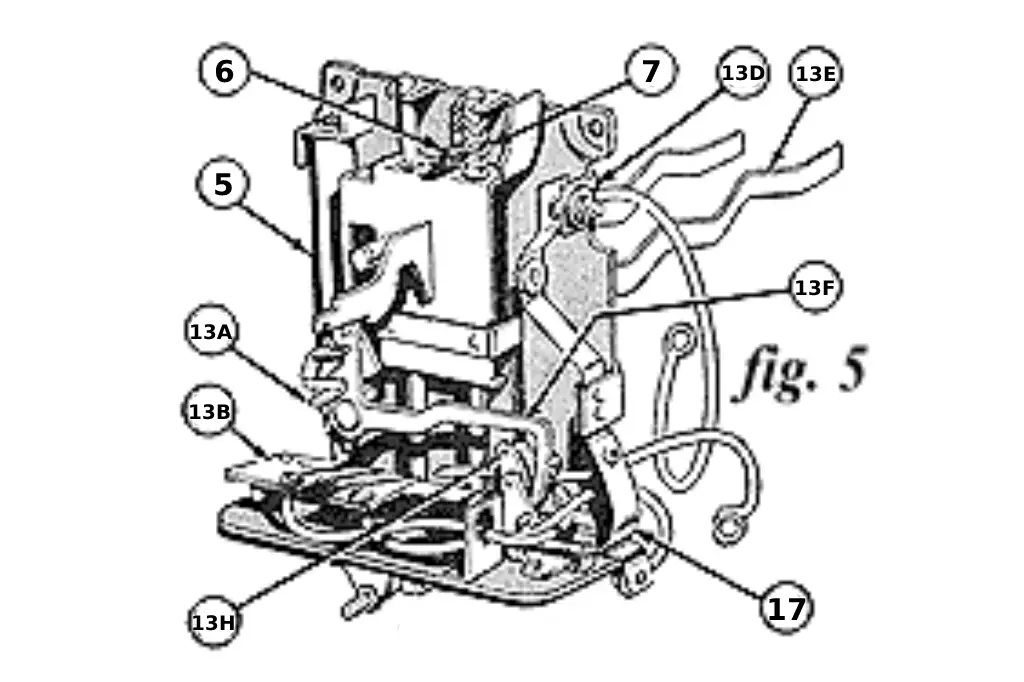

With reference to fig. 5 (below), showing the principal parts of a pop-up type of automatic toaster, the operation is as follows:

When the starting knob is pushed down, the latch lever (13F) engages the lower roller on the escapement (13H). At the same time the (13D) is closed, and the stove switch (17) is open.

The bimetal blade (13B) is thus heated by the stove unit, and the free end of the blade rises until it has raised the escapement lever high enough to disengage the latch lever from the bottom roller on the escapement (13H). When this occurs, the latch lever (13F) engages the top roller. At the same time, the stove switch contacts close, cutting the stove unit out of the circuit. When the stove is cut out of the circuit, the bimetal blade begins to cool with the resultant lowering of the free end of the blade. The escapement lever follows the bimetal blade in its return to normal. Finally the latch lever (13F) disengages from the top roller, and the starting lever, toast rack, etc., return to their starting positions. At the same time the main switch (13D) opens, thus completing the toasting cycle.

Movement of the switch-control arm moves the contact-lifter bracket and lowers the gravity-switch arm until its contact rests on the stationary contact and completes the electrical circuit. The upper part of the contact lifter bracket, which protrudes from the top of the control box, falls toward the hooked end of the thermostat assembly. In addition, the movement of the crank assembly permits a spring to slide the jam plate along the latch bar.

The circuit being closed, the heater element commences to toast the bread. The continued current flow expands the hot wire to allow the jam plate to slide farther along the latch bar. The main bimetal strip, being mounted close to the bread to be toasted, bends in response to the surface temperature of the bread, with the result that when the bread is fully toasted, the hooked end of the wire extension of the bimetal is pushed against the top of the contact lifter bracket to separate the contacts and interrupt the circuit.

With the circuit open, the hot wire cools, contracts and pulls back on the pivot yoke and jam plate, which is now locked or jammed on the latch bar. As the latch bar moves, it disengages the latch keeper which with the aid of the bread lifter spring actuates the carriage, removing the bread from the toasting position.

The controls are now ready for the next toasting. If this operation takes place immediately after the first toasting cycle, that is, while the toaster is still hot, the compensator bimetal due to its slight bend works in the opposite direction to that of the main bimetal and in this way a somewhat shorter toasting period will be obtained, thus preventing over-toasting of the bread at all times.

The third type of automatic “pop-up” toaster is equipped with a clock mechanism to control the toasting cycle. In a toaster of this type, the operating lever, which performs the function of lowering the bread into the oven, closes the electrical circuit and winds the timing mechanism which is automatically locked until released at the end of the correct time interval.

To obtain variations in timing, the speed of the clock is varied by means of a timing button. Thus, turning the button to the right increases the speed of the clock and turning to the left decreases the speed. Therefore, the position at which the timing button is set determines the color of the toast.

Certain late model toaster units of this type are equipped with a flexible clock having double wound elements and a shunting switch in the base of the toaster. The purpose of this construction is to increase or decrease the resistance of the heating units to obtain the desired wattage in localities where the voltages differ greatly.

For low-voltage ranges, the shunting switch in the bottom of the toaster is set to shunt out the extra winding, decreasing the resistance of the heating units. If the elements operate at too high a temperature with the shunting switch set in this position, the switch should be opened which increases the resistance to obtain satisfactory operation on the higher voltage ranges. With the switch closed (high) the toaster operates satisfactorily at an applied voltage at the toaster terminal of from 103 to 112. With the switch open (low) it operates satisfactorily on a voltage range from 110 to 120.

In this toaster the bimetal strip in the timing mechanism is heated by an auxiliary element connected in series with the main toaster elements. The flexing of the bimetal strip controls the toasting cycle. It is voltage-compensating and will automatically increase or decrease the toasting time if used within the limits of 105 to 120 volts.

For more information on toaster power consumption please refer to this article.

A heat-up, cool-off cycle controls the timing operation. During the heat-up part of the cycle, the auxiliary element heats the bimetal strip, causing it to flex. This action forces the operating arm slowly forward until it hits the timing shaft. The bimetal strip still heating, then flexes in the opposite direction until it has moved off the shunt-lever trigger. This causes the auxiliary switch to close and shunt out the auxiliary element. The release link then drops in the path of the operating arm.

At this point, the cool-off part of the cycle begins. The operating lever moves back toward the starting position until it comes in contact with the release link, moving the release lever until the toaster trips. The toast automatically pops up, opening up the main switch and shutting off the current. The entire timing mechanism is now reset for the next operation.

There you have it. The operating process of the electric toaster with all its components. While it might seem simple, there’s a lot going on inside your toaster.

How Hot Do Toasters Get?

Toasters can reach temperatures ranging from 300°F to 500°F (150°C to 260°C), depending on the model and selected toasting setting. The coils within the toaster can reach temperatures as high as 1000°F (520°C).

Do Toasters Have Timers?

To keep costs down, toasters typically do not use timer chips. Instead, they rely on bimetallic strips, which respond to heat by producing mechanical displacement. When heated, the strip curves and serves as a timer for the toasting process. The dials on the toaster allow users to adjust the curvature of the strip, determining how far it must curve before the bread is ejected.

This simple yet effective mechanism allows for precise control over the toasting process without the need for expensive electronic components.

Complex, Yet so Simple

While toasters may seem like straightforward electrical appliances, there is actually a surprising amount of engineering and science that goes into their operation. Whether it’s the use of radiant heat and bimetallic strips or the careful control of temperature and toasting time, toasters are intricate devices that have been refined over many years. And yet, despite this complexity, toasters remain a ubiquitous and essential part of our daily routines, helping us start the day off right with a delicious breakfast.